The world needs more ventilators – but scaling up production is more complex than it seems. Around the world, thousands of volunteers are working hard to fill the gaps.

As the coronavirus crisis accelerates, hardware experts and enthusiasts around the world are hearing the call of duty. They are responding one social media post at a time. “I saw an Instagram post from a friend in Barcelona,” says Martin Serey, co-founder of Pomo, a medical equipment start-up in Chile. “I woke up one day feeling we had the same problem here, as coronavirus cases will ramp up quickly.” In response, Serey’s company stopped their development of a prosthetic aid for stroke patients and started to think about how to do a ventilator.

There are not enough ventilators available in hospitals right now for all of the potential patients who will be struck by the virus. An influential report from Imperial College London estimates that 30% of Covid-19 hospitalised patients are likely to require mechanical ventilation. The only way to avoid overwhelming intensive care units, it says, is with a mandatory lockdown that reduces social contact by 75%.

But some countries have been slow to act accordingly – and it is still uncertain that we can sustain extended isolation measures over the “several months” they may be needed. As a result, a ventilator shortage remains imminent in many parts of the world, as New York Governor Andrew Cuomo’s plea for 30,000 units shows.

In terms of their core function, ventilators are not extraordinarily complicated machines. Basically, they are sophisticated pumps – they control the oxygen and air flow from the patient’s lungs, supporting them while they cannot do their work.

So why are they so difficult to design?

Because it isn’t their function that is difficult. It’s that they have to operate in an extremely reliable way in a high-stakes environment.

“If they fail, the patient is very likely to die,” explains Mauricio Toro, a Colombian engineer who joined a group in Medellin that completed the design of three different open-source ventilators. “This is what makes them so challenging to build.”

If they fail, the patient is very likely to die. This is what makes them so challenging to build – Mauricio Toro

As intensive care units overcrowd and doctors must care for more patients, the reliability of the machines cannot be in question.

But the only way to make them reliable is extensive testing, and that takes time – up to two years of testing, for commercial manufacturers. This is an extremely long period under the circumstances. Many more ventilators are needed now, not later. And scientists have calculated that the development of a vaccine against Covid-19 could take up to 18 months.

The race is on

Governments and health authorities are keenly aware of the challenge. The UK government aims to add more than 1,200 ventilators to its system in less than two weeks, and is forecasting it will need 30,000 at the peak of the outbreak. For that, it has called on non-health industries and universities to help in a wartime-like effort.

Philips, one of the top medical equipment companies worldwide, told BBC Future that it is “adding manufacturing lines and increasing the number of shifts, and hiring additional manufacturing employees and shifting current employees to support increased demand immediately”. Many other big corporations are following suit, even as their production capacity already has been strained due to the crisis and lockdowns in China.

Even Formula One racing teams are joining the effort. Dyson, the vacuum cleaner company, already received an order for 10,000 ventilators, and Smiths Medical’s efforts to treat less critical patients with CPAP (Continuous Positive Air Pressure) devices, more commonly used for controlling sleep apnoea, are advancing rapidly. Meanwhile, engineers and researchers are coming up with other creative solutions – such as the Ventil, a new machine that, when attached to a ventilator, can allow for the ventilation of two patients simultaneously.

But while high-income countries may have the possibility of scaling up an industrial effort in weeks, most countries do not.

And even high-income countries may find themselves in a position where they need additional ventilators, too: there are reports that prices are skyrocketing as the demand rises globally.

DIY devices

“You don’t want do-it-yourself ventilators out there if they don’t need to be. But if we reach the point where hundreds of thousands or millions of people are dying because there are not enough ventilators, then the DIY ones are the backup,” says Andrea Ippolito, a lecturer in engineering management in Cornell University who volunteers in a group called End Coronavirus, which is devoted to coordinating efforts between different DIY and open source ventilator projects.

If we reach the point where hundreds of thousands or millions of people are dying because there are not enough ventilators, then the DIY ones are the backup – Andrea Ippolito

As a result, thousands of experts, entrepreneurs and volunteers around the world are developing a different potential solution: creating open-source ventilators. With access to relatively simple designs, makers in Africa or South America could build ventilators quickly and cheaply using already available hardware and infrastructure. And since all the intellectual property of these projects will be free to use, licencing and copyright issues won’t get in the way of builders.

These designers are working at breakneck speed – at least a dozen ventilator prototypes at different stages have been developed in March 2020 alone by teams in different countries – and organising on Slack channels, Facebook groups, and GitHub repositories. They think they can help solve the bottleneck, particularly in parts of the world with less capability to respond to the crisis, like Africa or South America.

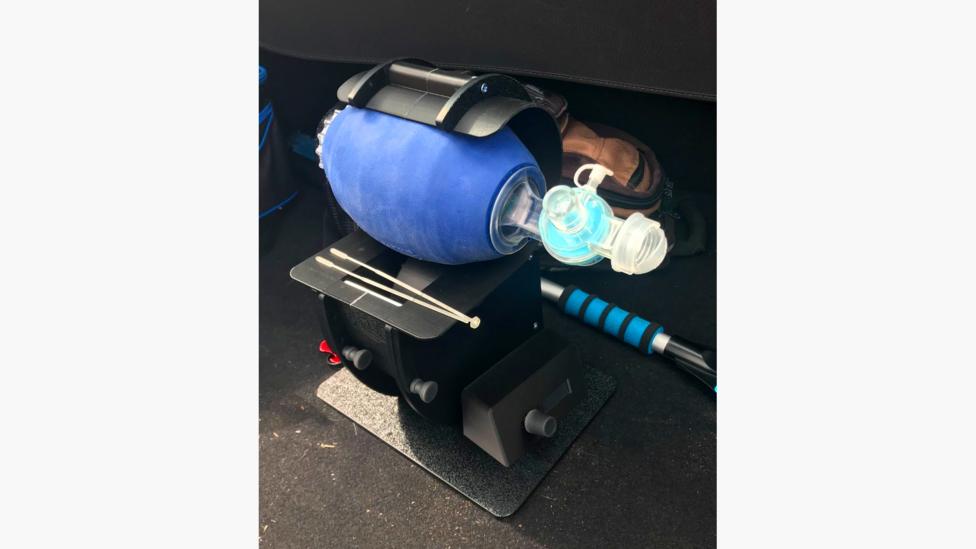

Some of the most basic open-source ventilator models are based on an ‘ambu-bag’ of the kind used by emergency teams (Credit: Dugan Karnazes)

Colin Keogh, an expert in 3D printing at University College Dublin, has been leading a team of volunteers looking at community-sourced and open-sourced projects. His team already has released a first prototype that works by automating “ambu-bags”, the pumps often used in ambulances and urgent care.

“We are just looking for a kind of very low-cost emergency ventilator system that could be provided as a last line of defence,” Keogh says. Its creators expect it to help doctors help patients in places with critical device shortages.

Pomo co-founder Serey’s idea is similar. It is an ambu-bag continually pushed by a lever moved by a small motor, programmed to push at different pressures and paces so the operator can control the air pressure and supply. Even more frugal than Keogh’s design, it does not use any 3D printed materials: it only requires string, a stand for the bag that could be easily made with aluminium or other materials, and an electric motor easily available off-the-shelf at hardware stores or at mechanic shops.

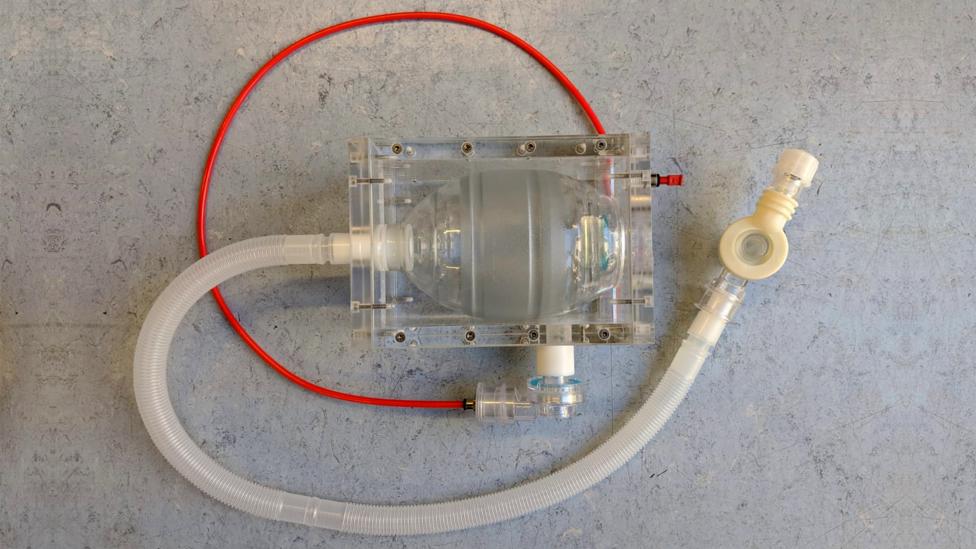

Other initiatives are more ambitious. Researchers from Oxford University and King’s College London set up OxVent, a project aimed at developing prototype ventilators “that are not as sophisticated as the ones that are currently used in hospitals, but that nonetheless meet the requirements in terms of safety and features that are required,” says Federico Formenti, a senior lecturer in Human Physiology at King’s College London who is part of OxVent.

The OxVent uses readily available materials, and is meant to be quickly buildable in university workshops (Credit: OxVent team)

Such a machine would not be intended to replace existing ventilators, but rather to support patients during the disease’s most acute phase and “provide an option for respiratory support to patients when hospitals run out of standard ventilators”.

Formenti’s team is trying to use widely available technologies and equipment, like parts already used by the NHS, generic electronics, and open-source software. “Our aim is to be able to produce these prototypes with components and materials which are available on the market, so people can build the device in, say, university laboratories,” says Formenti.

Road bumps

One obstacle that remains is testing.

Both the FDA and the MHRA set up fast approval processes for ventilators and other medical devices on the Covid-19 crisis, and Formenti says his team is readying steps to undergo MHRA testing in days’ time.

Other groups believe that will still take too long, so they’re working on other approaches. The End Coronavirus group, for example, is working towards developing or obtaining an “iron lung”: a machine that simulates the pressures and airflow of a human lung. Through these kinds of tests, they hope to produce enough proof for physicians to use them on patients – at least as a last resort. If a doctor must choose between using a ventilator tested only on an “iron lung” or nothing, the leaders of End Coronavirus believe doctors will opt for the former.

This ventilator model created by a university in Medellin, Colombia, is already being tested on animals (Credit: Universidad EIA)

Materials are another challenge. They should be able to endure extensive wear and tear, not be likely to spread infection, and hold up under different cleaning methods, like chemicals or UV. These requirements seriously entangle the design process, as they complicate engineering choices. “It cannot be a fire hazard, and oxygen is very corrosive for many materials,” says Medellin engineer Toro.

This can be tricky: for instance, while 3D printing process itself makes the devices sterile, the plastic used in it is very porous, so it is it difficult to keep pieces clean and safe once printed. It means the technique is best suited for creating disposable items and not for replacing conventional parts or entire machines.

Even if designers and engineers can solve all of this, the machines must be easy for health professionals to use, meaning they should be as similar to existing ones as possible or very simple to learn to operate. This is key in order for them to be useful in this crisis: the US National Academy of Medicine, for example, recommends hospitals “minimise the need to train staff” to operate ventilators so they can respond with the rising demand.

The machines must be easy for health professionals to use, meaning they should be as similar to existing ones as possible or very simple to learn to operate

Formenti and the OxVent team plan to create “a simplified version of what is available in the hospitals already”, so it should be easy for users to operate. However, this is still a work in progress for most initiatives. In one evaluation of 20 projects, it was found that only one of them was “clinician-friendly” enough to be usable.

Hospital doctors are taught how to handle a ventilator at the Universitaetsklinikum Eppendorf in Hamburg, Germany in March 2020 (Credit: Getty Images)

Another challenge is managing thousands of enthusiastic volunteers to work productively. It sounds like a good problem, but it is still a problem, says Diana Rodriguez, a US-based Venezuelan software developer who has worked in other health-tech open source projects: “Directing people’s efforts is going to be a huge challenge. Some people will work a lot and have a lot of knowledge, but this is very complex.” A sharp goal and a sensible division of labour are crucial: “Not everyone has the same skills, so people should do what they are good at.”

Fortunately, DIY makers and open-source software movements already have experience with these types of self-organising teams, so it’s a challenge that can be overcome.

And for most makers and designers, all of these problems are secondary compared to the importance of the goal: creating more ventilators to save lives. As Keogh says, “it just needs to be done.” This is why they’re putting in thousands of hours with little sleep and putting the rest of their lives aside. It could, literally, be a matter of life or death.

Source: Bbc Future